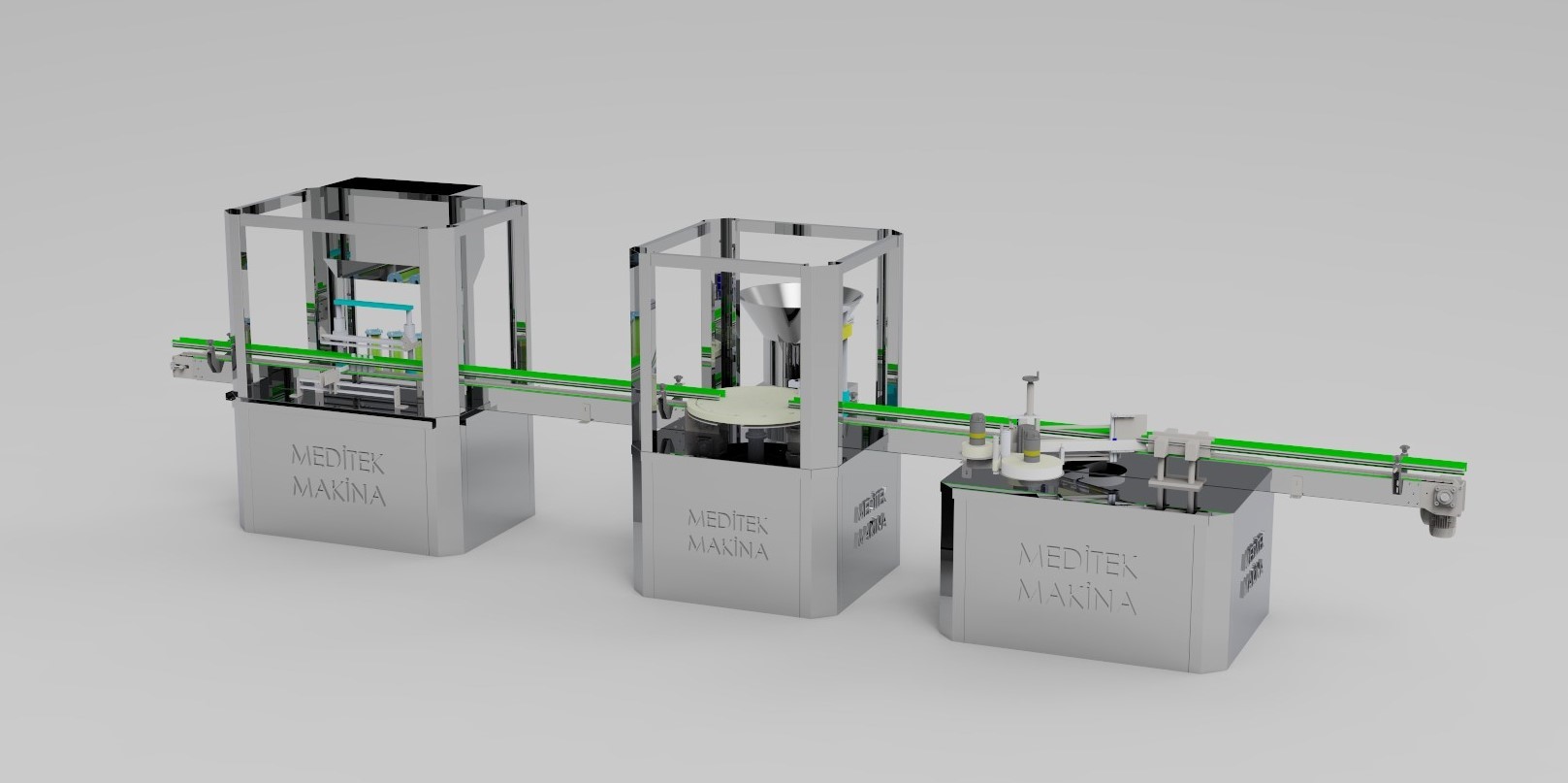

The 4-nozzle liquid filling line is a professional automatic liquid filling machine system developed for high-volume liquid filling operations. Equipped with a multi-block chassis or a linear line system, this line is designed to perform liquid filling and capping operations in sterile environments.

Thanks to the conveyor belt system, a seamless transition is ensured between the liquid filling machine and the capping machine. Electronic weight control can be carried out via the digital touchscreen according to the recipe. With its wide filling range, it is ideal for many liquid products. Production complies with GMP and GEP standards and is also compatible with IQ, OQ, PQ, and DQ documentation.

Machine Model: Automatic Liquid Filling Line

Machine Type: Liquid Filling Machine

Line Configuration: Linear Line (Linear Filling Machine)

Filling Type: Electronic Weight Control

Capping System: Automatic Cap Feeding and Capping

Capping System: Automatic stopper feeding and insertion depending on the product

Giriş ve Çıkış Ünitesi: Conveyor Inlet and Outlet

Power Supply: 380V

Power Consumption: 1,5 kW

Pneumatic Connection: 6–8 Bar

Air Consumption: 750 L/min

Capacity: 30 pcs/min (maximum)

Filling Accuracy: ±%2

Speed: Adjustable (with digital screen control)

Dimensions: Multi-block chassis with enclosed system

Shampoo filling

Honey filling

Jam filling

Lemonade filling

Drug filling

Cosmetic filling

Detergent filling

Cologne filling

The 4-nozzle liquid filling machine ensures maximum efficiency in high-precision liquid filling and capping processes. It is an excellent solution for those looking to establish an industrial production line.